Hydraulic Power Pack Manufacturers In Nashik

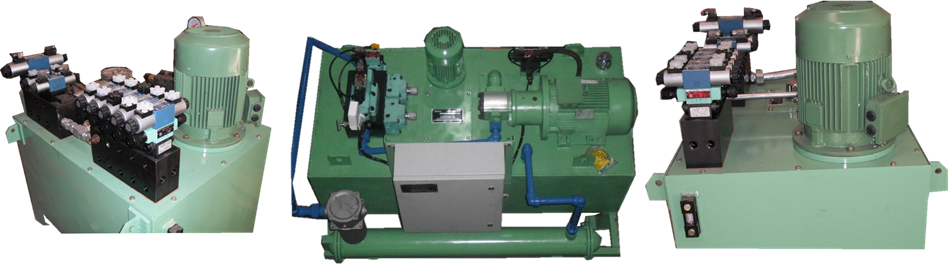

Vedant Engineering Services is one of the leading hydraulic power packs manufacturers and suppliers in India. We provide these power packs in both standard and custom built designs. Available in auto cut off and holding types these power packs have quality finish and hence paint them with epoxy paints / Powder Coating. We ensure that our power pack systems have compact design, rust free nature, quality cylinders with single / double acting Our range of hydraulic power packs components is tested on various parameters like durability, resistance, shelf life to ensure quality product to our customers.

Power pack offers capacities, control options & configurations for virtually any application requirement. A wide variety of Manifold option & choice of Pumps enables customer to match any application requirement with a power pack that, meets his system, at the same time ensuring cost effective operation and optimum productivity.

Beside supplying standard hydraulic power pack from our wide range, we specialize in designing and manufacturing hydraulic power pack as per customers, specific requirements.

Vedant Engineering Services specializes in developing hydraulic systems from enquiry to final commissioning and after-sales service. Numerous customized Hydraulic Power Pack specifically designed after understanding the users application & needs.

Numerous customized Hydraulic systems specifically designed after understanding the users application & needs.

♦ We have developed a dedicated “Hydraulic Power Pack Testing Machine”. Each and every Hydraulic System is delivered only after passing through this testing machine.

We are one of the renowned Hydraulic Power Pack Manufacturers In Nashik

Features of our Hydraulic Power Packs

| Tank | |

| Ø | Tanks are fabricated from mild steel or Stainless Steel and also from Die Cast Aluminium |

| Ø | Tanks are Designed with sufficient thickness to ensure strength and rigidity and mimimum weld joints |

| Ø | Tank Top Plate is Mild Steel, Stainless Steel or Aluminium of sufficent thickness to ensure rigid support to the whole assembly |

| Ø | All joints like top plate assembly to tank, pipe entries from top plate etc.are sealed using suitable elastomer |

| Ø | Manhole covers are provided in front of the tank to facilitate cleaning and maintenance |

| Ø | Baffle Plate is provided inside the tank to isolate pump suction from turbulence of return line |

| Ø | Following standard accessories are provided : |

| · Oil collection tray on the top in periphery

· Drain Valve · Air breather · Oil level Gauge · Inspection Cover |

|

| Ø | Following Optional accessories are provided : |

| · Oil Level Switch

· Temperature Gauge · Temperature Sensor, Digital Temperature Switch · Flow Meter and Flow Switch · Electrical Terminal Box |

|

| Ø | Mild Steel Tanks go through a 7 tank cleaning process after which they are phosphated and powder coated |

| Tubing | |

| Ø | Cold Drawn seamless tubes as per DIN2391 are used for piping |

| Ø | Ermetto bite type ferrule fittings are used for low pressures and weld-on-nipple or SAE flanges are used for high pressures |

| Ø | Tubes are suitably for oil velocity and pressure |

| Ø | All pipes are well supported using suitable clamps aesthetically laid out. |

| Ø | All pipes are pickled, Zink Plated and cleaned with kerosene before assembly |

| Ø | Hoses are used at locations prone to vibrations. |

| Motor – Pump Unit | |

| Ø | The unit is either mounted vertically with pump immersed inside the tank for positive suction and low noise level or horizontally for ease of replacement as per choice |

| Ø | Generally 15HP and above installations are Horizontal and on anti – vibration pads and a common plates |

| Ø | Large pump-motor assemblies are also mounted at the side of the tank for positive suction. They are provided with isolation ball valves, flexible bellows |

| Ø | The units are coupled with bell housing and flexible drive couplings |

| Ø | Location Markers are provided for ease of re-assembly |

| Hydraulic System | |

| Ø | System is design for the operating logic with multiple flow and pressure controls as desired. |

| Ø | System is Design with adequate care to ascertain the right sizing and selection of component taking into account the application and duty cycle |

| Ø | Tank is sized to take care of oil level fluctuation and heat dissipation |

| Ø | Systems are designed with energy conservation with the help of high – low circuits, accumulators and variable delivery pumps |

| Ø | Systems are designed to start on “No Load” and Idle running with Venting Fecility. |

| Ø | Systems are designed with Pilot Check valves in Pressure holding circuits, Reducing valves for separate Low Pressure setting, Sequence valves and Pressure Switches for Sequencing circuits, Pressure Compensated Flow control valves for precise speed controls, Counter Balance valves for falling load support, Catridge valves for high flows and smooth operation, Pressure Switches, Pressure Transducers and Hose Burst valves for Safety as per the requirement of applications |

| Ø | Systems are also designed for Closed Loop applications with Proportional valves for high accuracy and automation controls. Systems are also designed with Hydro – Static Drives |

| Ø | Systems are Manifolded to a large extent for following adventages |

| · Compact Construction

· Reduction of tubing and number of leakage points · Improve the System stiffness and Performance · Facilitate maintenance |

|

| Ø | Systems are provided with good quality pressure guages with isolator for safety. In addition, extra guage points also provided with minimess coupling to fecilitate maintenance |

| Ø | System is Designed using all standard makes such as Yuken, Vickers, Denison, Bosch – Rexroth, parker, Dowty, Siemens, Bharat Bijlee, Hydroline, Bhagwati, stauff, Waree, Wika, GIC, Shridhan, etc. |

| Ø | All Fasteners used in the system are 8.8 class or better |

| Oil Filtration and Contamination Control | |

| Ø | Pump Suction are provided with 149 micron mesh type strainers or filters as standard |

| Ø | Return lines are provided with 10 or 25 micron suitably sized filters as standard |

| Ø | Pressure lines filters of 3, 5, 10 microns with absolute beta reating better then 200 are provided if required |

| Ø | Continuous off-line Filtration system are also provided if desired |

| Ø | Magnatic Tank cleaners Suspended inside the tank are also provided if required |

| Ø | Manifold blocks are initially deburred and cleaned. then they are heated at high temperature to malt the low mass metals particles and then blackodised. They are cleaned with high pressure kerosene before assembly |

| Ø | Tubes are also burnt at high temperatures to melt low mass metels particles and then Zinc Passivated |

| Oil Cooling | |

| Ø | Firstly tanks are sized suitably to provide natural cooling to maintain oil temperature below 15° C above ambient |

| Ø | If the natural cooling is not suffcient then additional water cooled or air cooled heat exchangers are provided in the systems,These are either water cooled shell and tube type / Plate type or air cooled Radiator type coolers |

| Ø | Tank submersed heat exchangers are also provided as a special case. |

| Ø | Continuous Off – line Cooling systems are also provided if desired. |

Click here for common features of our Hydraulic Systems >

Hydraulic Power Packs Manufacturers in India, Hydraulic Power Pack Suppliers in India, Custom Hydraulic Power Packs as per requitrements.

Hydraulic Power Pack Manufacturers in Nashik, Hydraulic Power Pack Manufacturers in Maharashtra, Hydraulic Power Pack Manufacturers in Pune, Hydraulic Power Pack Manufacturers in Mumbai, Hydraulic Power Pack Manufacturers in Aurangabad, Hydraulic Power Pack Manufacturers in India, Hydraulic Systems Manufacturers in Nashik, Hydraulic Systems Manufacturers in Maharashtra, Hydraulic Systems Manufacturers in Pune, Hydraulic Systems Manufacturers in Mumbai, Hydraulic Systems Manufacturers in Aurangabad, Hydraulic Systems Manufacturers in India.