Hybrid Energy Saving System (HES) for Hydraulic Machines

Delta’s Hybrid Energy Saving (HES) System provides precise pressure and flow controls for each injection molding process and also solves the energy waste issues of a traditional injection molding machine. This solution helps to improve product quality, market competitiveness and productivity.

Product Introduction

Features & Benefits

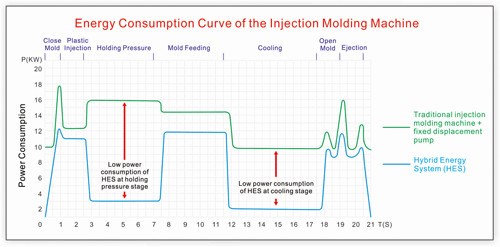

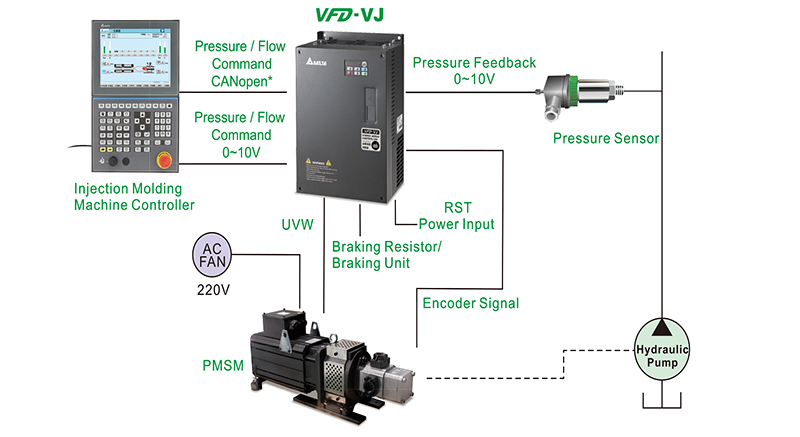

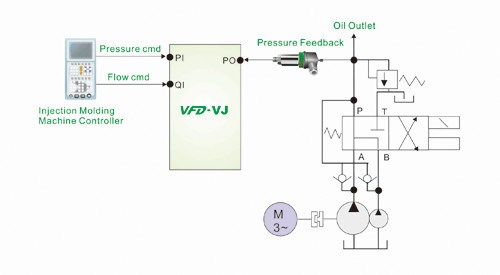

Any Hydraulic machine play a key role in products production. There are four major energy consuming units in a traditional machine including the hydraulic pump, the heating unit, the cooling system, and the control system components. The hydraulic pump system consumes the most energy and accounts for more than 75% of the total power consumption in an manufacturing process. An machine cycle consists of several stages from mold closing, injection, pressure holding, plasticization, mold opening to ejection. Each stage requires a different pressure and flow. The oil pump motor is under variable loading. Traditionally, the overflow valve and the ratio valve adjust the excess pressure and flow that occurs at each stage. This process is known as “high-pressure throttle”. It accounts for 40%~75% of the energy loss. The Delta Hybrid Energy Saving System HES-C Series provides precise pressure and flow control, eliminating energy loss in the high pressure throttle process. It helps injection molding machines save energy while enhancing productivity and precision. The Delta HES Series provides the best solution for injection molding machines.

- Superior Energy-Saving Outcomes: Lower energy consumption rate at the clamping and cooling stage while providing high productivity and high precision. 40% less energy consumption compared to a variable pump hydraulic systems. 60% less energy consumption compared to a traditional quantitative pump hydraulic system.

- Low Oil Temperature: Oil temperature reduced by 5~10℃; oil usage reduced by 50~60%; requires 50% less oil tank volume; lower cooler specifications required and for some cases cooler is not required.

- High Duplication Accuracy: Precise flow and pressure control featuring duplication of products with less than 0.09% difference.

- Long Holding Pressure: Keeps mold halves securely closed for a longer period for thick plastic products formation.

- Good Frequency Response: When uses Delta HES with permanent magnetic servo motor (PMSM) speeds up frequency response to 50ms.

- Suitable for Harsh Environments: The resolver used in Delta HES is resistant to earthquakes, oil and dust.

- Old Machine Replenishment: Supports analog command 0~10V and linear correction (3 points), no replacing.

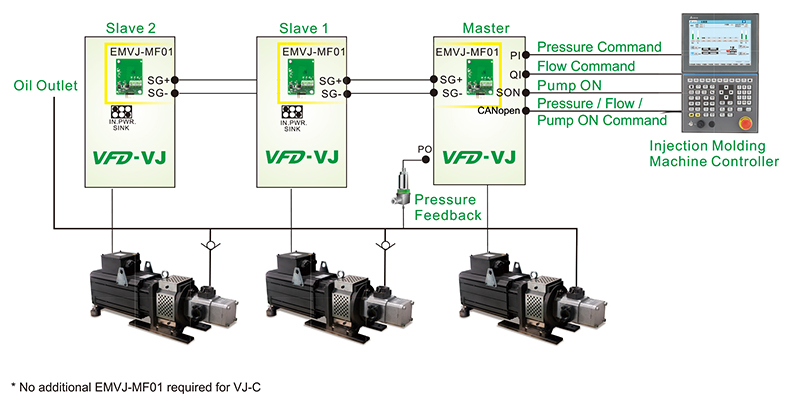

- Flow Convergence: Saves cost on tubes, large flow capacity, enhances energy-saving.

System Structure

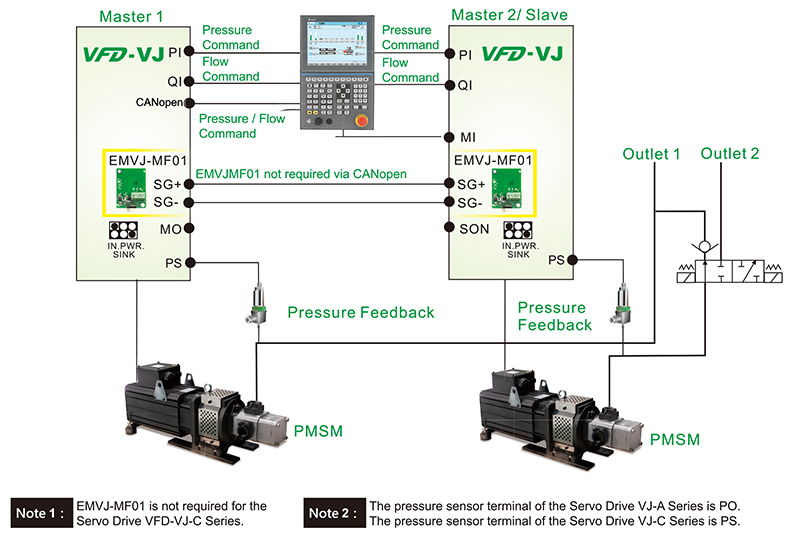

Convergent Flow Multiple Pumps

Flow Capacity Switch

Convergent Flow / Divergent Flow

Applications

- Injection Molding Machine

- Die Casting Machine

- Hydraulic Machine

- Hydraulic Press

Servo Motor for Hydraulic Press, Servo Motor for Injection Molding Machine,

servo drive for plastic injection machines, Servo Drives for Hydraulic Press and machines Nashik Maharashtra.